LN solves temperature instability issue on ketchup deaerator

DownloadThe Application

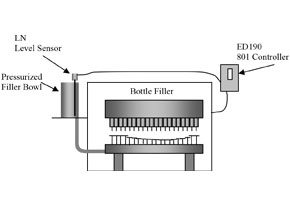

Pressurized Filler Bowl for Ketchup Replacing Mechanical Float with Pneumatic Output

Pressurized Filler Bowl for Ketchup Replacing Mechanical Float with Pneumatic Output

The Requirements

The Anderson-Negele Solution

We supplied a LN Potentiometric level sensor mated with an ED190 to the plant for their evaluation. For this application the ED190 was equipped with 801 controller, I/P transducer, and an independent 24v power supply. The original mechanical float was side mounted, however an existing 2”TC pressure gauge port allowed for a convenient top mount installation. The ED190 was mounted to the control panel then power and the pneumatic lines were run to the box. The resulting “pneumatic” level control system provided the plant a state of the art electronic level transmitter that was immune to the affects of temperature and product coatings, eliminated the periodic maintenance required for moving parts and significantly improved CIP cleanability. Additionally the standard 801 relay output was utilized as a local high level alarm for the operator. The accuracy and stability of the LN along with the increased functionality, simplicity and “retrofitability” of the complete package has lead to the ongoing retrofit throughout the plant.

We supplied a LN Potentiometric level sensor mated with an ED190 to the plant for their evaluation. For this application the ED190 was equipped with 801 controller, I/P transducer, and an independent 24v power supply. The original mechanical float was side mounted, however an existing 2”TC pressure gauge port allowed for a convenient top mount installation. The ED190 was mounted to the control panel then power and the pneumatic lines were run to the box. The resulting “pneumatic” level control system provided the plant a state of the art electronic level transmitter that was immune to the affects of temperature and product coatings, eliminated the periodic maintenance required for moving parts and significantly improved CIP cleanability. Additionally the standard 801 relay output was utilized as a local high level alarm for the operator. The accuracy and stability of the LN along with the increased functionality, simplicity and “retrofitability” of the complete package has lead to the ongoing retrofit throughout the plant.

Typical Applications

- Deaerator

- Rotary jug fillers

- Stationary fillers

- Pressurized fillers

- Scrape surface processors

- CIP skids

- Pressurized process vessels

- Balance tanks

Copyright © 2015 Anderson-Negele